Listen to the full episode here :The Daily Dose Podcast Audio

How Is CBD Manufactured Now

CBD And Manufacturing

Welcome back everyone today we are going to clear up some confusion around the CBD world of products as I continue to get questions and confusions around CBD products including why some are stronger or why some are pricier than others.

When comparing market rate and pricing many discover it can be expensive or in expensive depending on what your buying. So naturally we should answer these questions and concerns so that you may be able to make better choices around what you should or shouldn’t buy and why.

So many of you may have tried CBD already it’s been around for many years now, you may not know that I being one of the first retailers to carry CBD have seen and tried so many and along the way we have learned so much about the different variations of Cannabidiol such as Isolate, broad spectrum and of course full spectrum.

These have a variable of influence on cost and effect. Determining which one depends on needs and what it is you want it to do, then we also have quality such as how it’s manufactured and best practices.

Many don’t realize there is in fact significant differences between the three options including how they are actually extracted from the plant. In this episode I’ll share with you the differences the preferred methods and what you should be looking out for as you go on the hunt for a product you want to use for your specific needs.

Remember everyone is different and so you should consider what you want to address and speak with someone who may be able to guide in the right direction so you can discover for yourself the wonders of Cannabidiol and how millions everyday are talking about the benefits they are getting.

Introduction

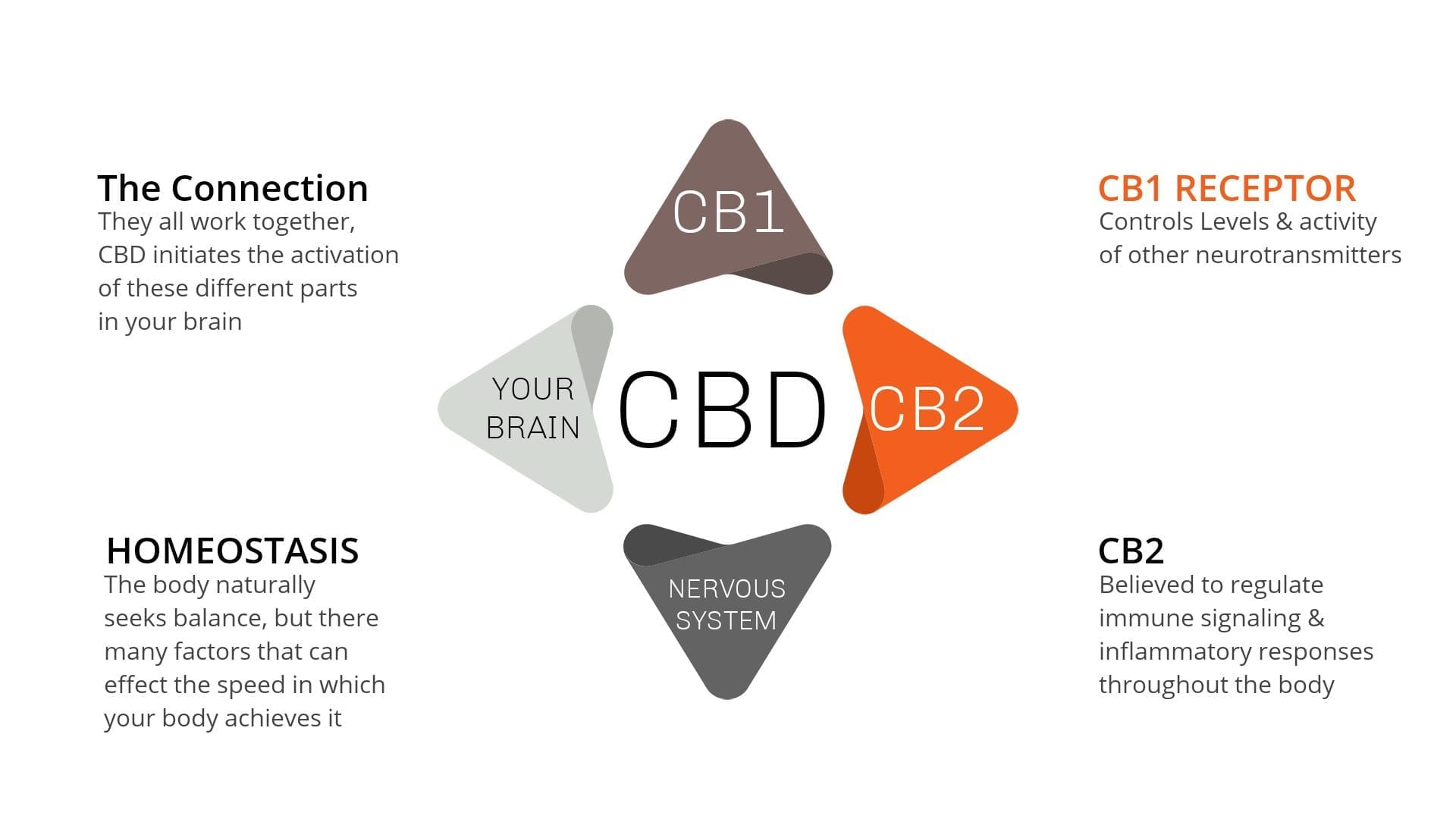

The manufacturing of CBD (cannabidiol) has become a prominent industry, driven by its numerous potential health benefits. CBD is one of the many compounds found in the cannabis plant and is renowned for its non-psychoactive properties.

This article explores the journey of CBD from its source, the hemp or cannabis plant, to the various forms available on the market, providing insights into the cultivation, extraction, refining, testing, and product development processes involved.

The Source of CBD

Hemp and Cannabis CBD can be sourced from two primary varieties of the cannabis plant: hemp and marijuana. Hemp, which contains less than 0.3% THC (tetrahydrocannabinol, the psychoactive compound in cannabis), is the preferred source due to its legal status in many countries. Marijuana, on the other hand, contains higher levels of THC and is subject to more stringent regulations.

Cultivation and Harvesting

The journey of CBD begins with the cultivation of hemp plants. These plants are typically grown outdoors in large fields or indoors in controlled environments. The choice of cultivation method depends on factors like climate, regulations, and space availability.

Hemp plants are typically grown from seeds or clones and require specific care, including proper watering, nutrition, and pest control. Once mature, the plants are harvested, typically during the late summer or early fall, before being transported for processing.

Extraction Methods

After harvesting, the CBD must be extracted from the plant material. Several extraction methods are used to accomplish this, each with its unique advantages and disadvantages.

| Solvents | CO2 | Ethanol | Hydrocarbon | Lipid Extraction |

|---|

Solvent-Based Extraction Solvent-based extraction involves the use of a liquid solvent (e.g., ethanol, butane, or propane) to dissolve the cannabinoids and other compounds present in the plant. The resulting solution is then heated to evaporate the solvent, leaving behind the extracted CBD oil. This method is efficient but requires careful solvent removal to ensure product safety.

CO2 Extraction Carbon dioxide (CO2) extraction is one of the most advanced and preferred methods for extracting CBD. It uses pressurized CO2 to create a supercritical fluid, which can effectively extract CBD and other cannabinoids. CO2 extraction is highly precise and ensures minimal residue, making it a popular choice for high-quality CBD products.

Ethanol Extraction Ethanol extraction uses ethanol (alcohol) to draw out cannabinoids and other compounds. It is a cost-effective method, but it may also extract undesirable substances, requiring additional refinement.

Hydrocarbon Extraction Hydrocarbon extraction involves using hydrocarbons like butane or propane. It’s highly efficient but must be conducted with precision to avoid safety risks, as these solvents are flammable.

Lipid Extraction Lipid extraction is a less common method that uses fats or lipids to extract cannabinoids. This process involves steeping plant material in oil, such as coconut or olive oil, to produce CBD-infused oils or tinctures. It’s simple but may result in lower CBD concentrations.

Refining and Purifying CBD

Once extracted, CBD oil may undergo further refinement to remove impurities and unwanted compounds. Common refining techniques include winterization, which removes waxes and lipids, and chromatography, which can further isolate individual cannabinoids.

CBD Isolate vs. Full-Spectrum CBD

After refining, CBD can be categorized as either an isolate or full-spectrum CBD. CBD isolate contains only pure CBD, while full-spectrum CBD includes a range of other beneficial cannabinoids, terpenes, and flavonoids present in the hemp plant. The choice between the two depends on the desired effects and legal considerations.

Quality Control and Testing

Quality control is a crucial step in CBD manufacturing to ensure product safety and consistency. Third-party testing labs play a vital role in verifying the content and purity of CBD products.

Third-Party Testing Third-party testing is essential to eliminate any potential biases in product quality assessment. Independent labs test CBD products for cannabinoid content, contaminants, heavy metals, and pesticides, among other factors.

Certificate of Analysis (COA) A Certificate of Analysis is provided by these labs and is often made available to consumers, detailing the product’s cannabinoid profile and safety information. This transparency ensures that consumers can make informed choices when purchasing CBD products.

Formulation and Product Development

CBD is used in various products designed to cater to different needs and preferences. The manufacturing process for CBD products involves formulating the CBD extract into various delivery methods.

| Tinctures | Capsules | Edibles | Topicals | Vapes | Other Products |

|---|

Tinctures CBD tinctures are one of the most popular forms of CBD products. They consist of CBD extract mixed with a carrier oil, often administered sublingually for fast absorption.

Capsules CBD capsules contain pre-measured doses of CBD, making them convenient for those who prefer a more controlled intake method.

Edibles CBD-infused edibles, such as gummies, chocolates, and beverages, provide a tasty and discreet way to consume CBD.

Topicals CBD topicals include creams, balms, and lotions infused with CBD, ideal for localized application to target specific areas.

Vaping Products Vaping products, including e-liquids and vape pens, allow for the inhalation of vaporized CBD for rapid absorption.

Other Products The CBD market is continually expanding, leading to the development of various innovative products, including CBD-infused skincare, pet products, and more.

Packaging and Labeling

Proper packaging and labeling are essential to ensure product safety and compliance with regulations. CBD products must provide clear and accurate information on dosage, ingredients, and usage instructions.

Conclusion

The manufacturing process of CBD involves a series of intricate steps, from the cultivation and extraction of the hemp plant to the formulation of various CBD products. Quality control, safety testing, and proper packaging are crucial to delivering consistent and safe CBD products to consumers.

As the CBD industry continues to grow and evolve, these manufacturing processes will only become more refined, ensuring that consumers have access to high-quality CBD products with the potential to improve their well-being.

FAQs

What are some common confusions around these products?

What are the different variations available in the market?

How can one determine which type to choose?

What are some significant differences between the three options?

What should consumers consider when looking for a product?

Related Articles:

- CBD For Cancer: Benefits, Dosage, and Risks

- CBD for Addiction Recovery: Healing Now

- Immune Support How CBD Can Help

- Top CBD Cream Relieves Arthritis Pain Now

- Discover CBD Now Benefits Explained

Meet The Author